Water Cooling System for QSMotor 17in 8kW Hub Motor

An old Kawasaki Z650 motorcycle was converted to an electric drivetrain using this hub motor for the rear wheel. The motorcycle does ~55-60mph with a power consumption of roughly ~6-8kW with roughly ~120A of phase current. Over extended periods of time at this speed, the motor will tend to overheat, reaching internal temperatures of 90C after 20 minutes, and reaching 130C for short bursts at ~600A of phase current. Therefore, a water cooling system was developed to keep temperatures under control and boost power output.

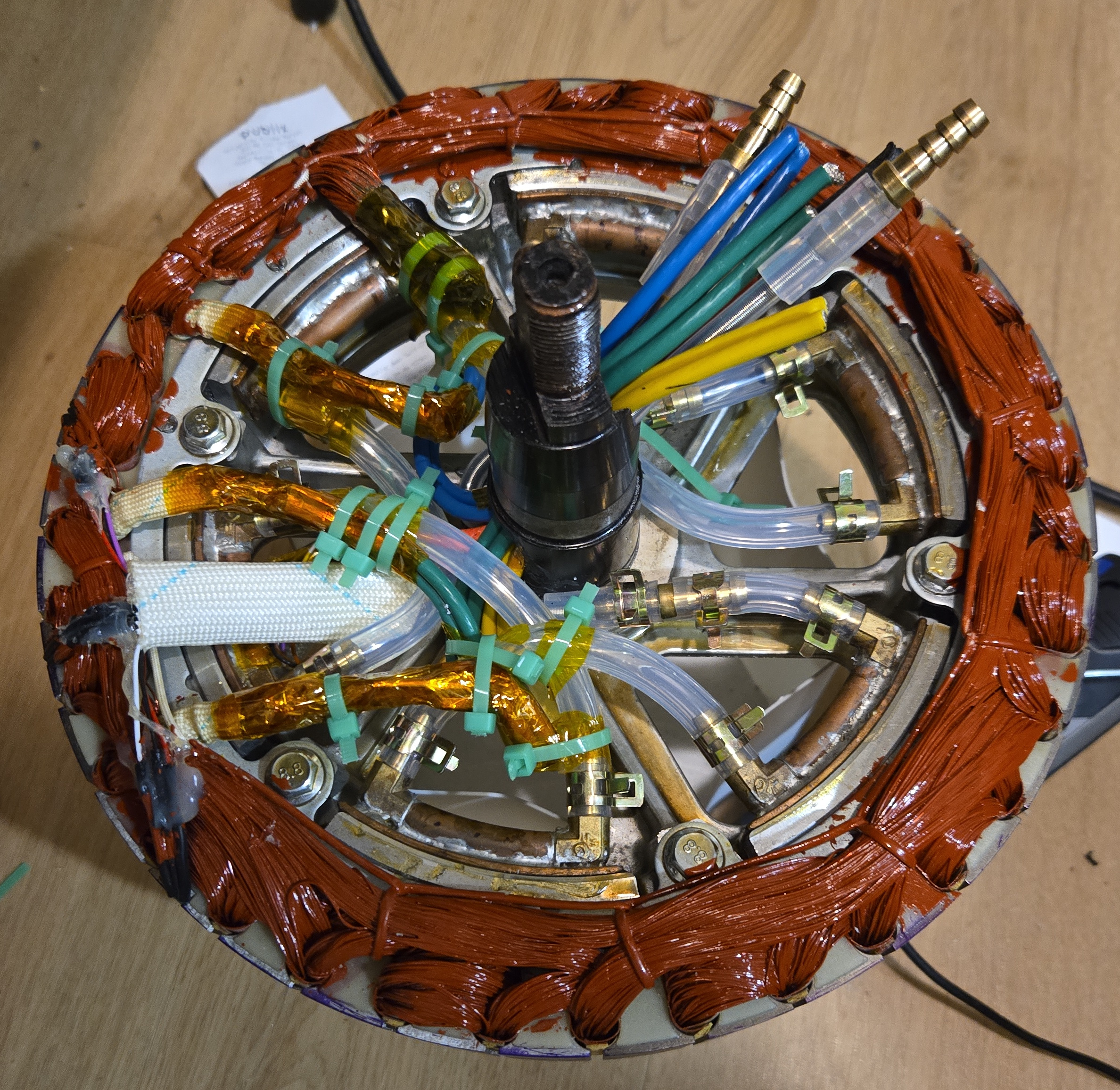

Custom waterblocks were created for the motor out of 2mm x 20mm copper plate cut to ~65mm length, copper tubing 3/8" OD 5/16" ID, and 90deg 1/4" barb brass elbows. The copper plate and tubing was bent to match the curvature of the inside of the stator, and the lengths of the barbs were cut to fit inside of the copper tubing and stator. The individual parts are shown below:

The parts were soldered together using plumbing solder, flux, and a propane torch. Seven water blocks were made in total; six for the stator segments and one spare.

After leak testing to 90 PSI using a bicycle pump and a bucket of water, the water blocks were glued into the stator using 3M DP810 toughened acrylic adhesive.

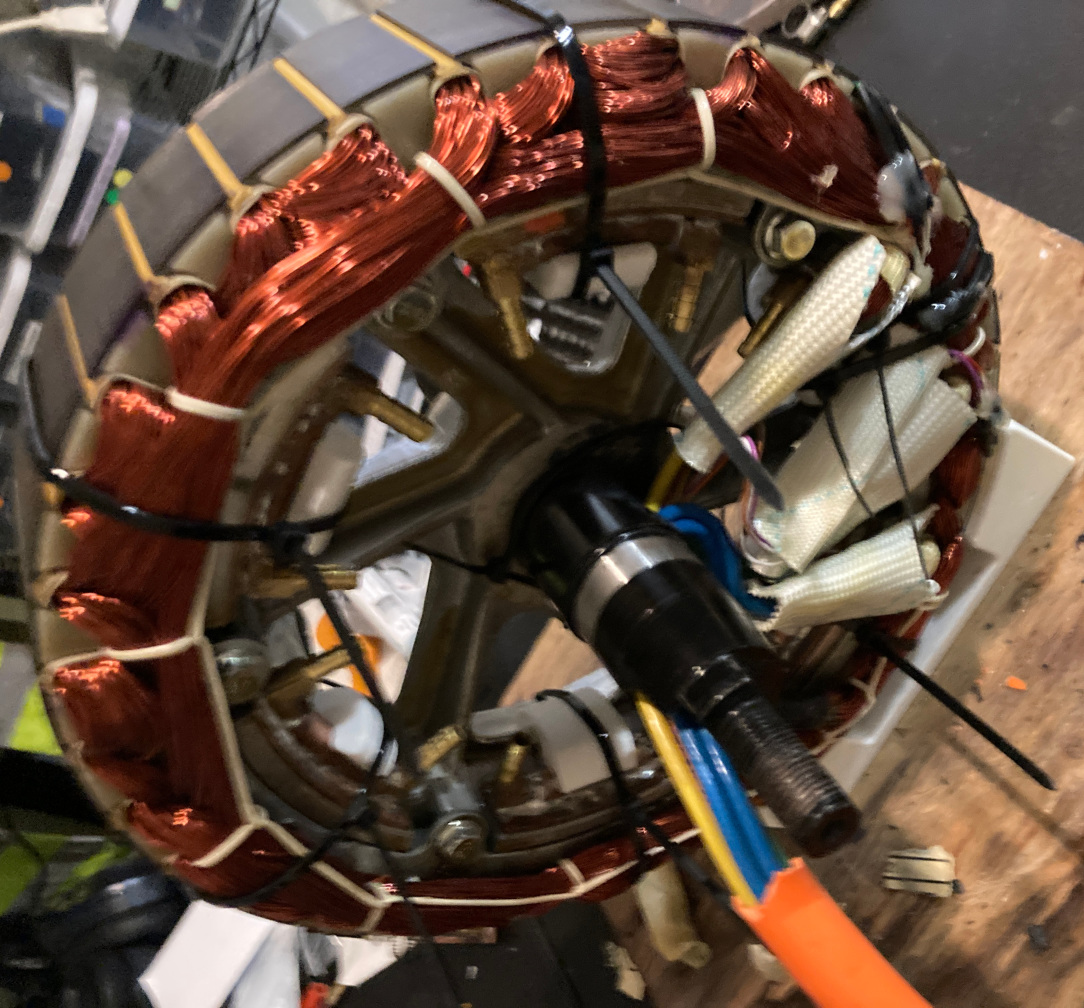

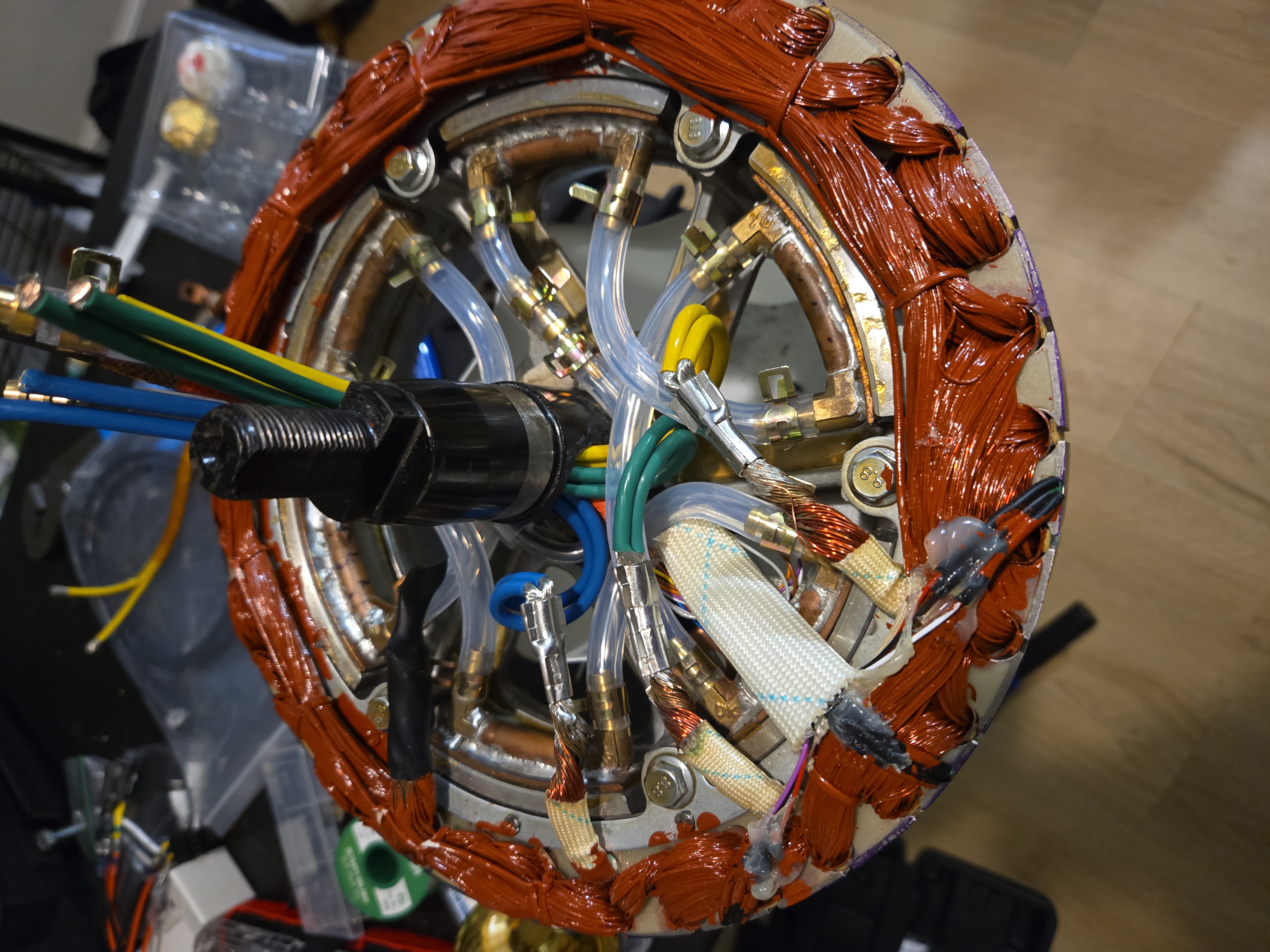

After gluing, the water blocks were connected using 1/4" silicone tubing and spring band hose clamps for vibration resistance. Additionally, MG Chemicals 4228A-55ML Red Insulating Varnish was applied to the stator windings for improved vibration resistance and better heat conduction.

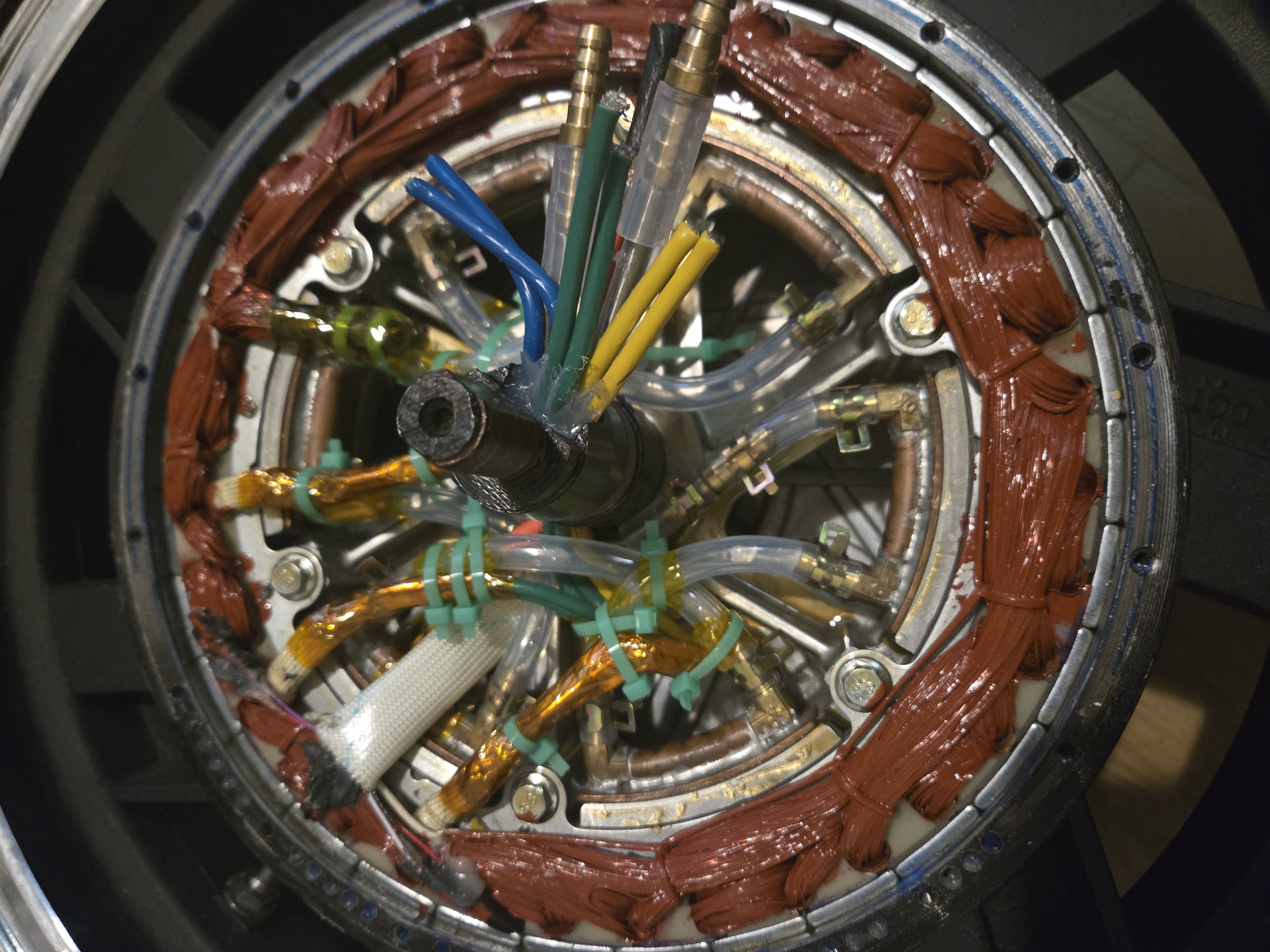

Routing the coolant tubes through the hole in the shaft of the motor was challenging. To make enough room, the outer insulation was stripped from the cable to the motor. Standard 1/4" tubing wouldn't fit, so thinner silicone tubing with a 4mm ID and 6mm OD was used instead. To avoid kinks and buckling of the tube, 0.4x4mm springs were run along the inside. This results in increased flow losses, but so do all the 90 degree elbows, and the more predictable bending behavior was deemed an acceptable tradeoff.

The tubes and wires were secured using high temperature sip ties, and connections were insulated with kapton tape.

Finally, the front cover was bolted on with silicone gasket adhesive as a sealant. Lugs were crimped onto the wires, and silicone dielectric grease was applied inside of the shaft as a water barrier. However, this may not be effective for keeping the motor waterproof.